YOUR ONE-STOP LOCATION FOR ALL YOUR CAST POLYURETHANE NEEDS

Fully Automated Dispensers

With more than 50 years of experience in the cast polyurethane industry, and by employing state-of-the art computer and instrumentation technology, we have developed a polyurethane metering and mixing machine that consistently delivers quality cast elastomers.

StateMix urethane dispensers can be set up easily and are capable of metering and mixing various polymers such as MDI, TDI, and rotational casting systems.

Flex Cell Hand Batch Stations

The StateMix automated hand-pour dispenser is designed for processing a variety of hot cast or room temperature polyurethane or epoxy materials in a compact and economical workstation.

Vortex Mixers

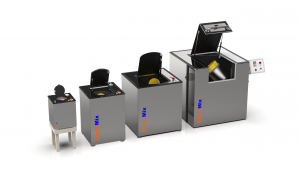

The Vortex Mixer is designed to mix hard-to-blend materials over a wide range of viscosities and comes in 5 sizes to cover a variety of mixing applications.

Materials, including polyurethanes, silicones, inks, waxes, filled polymers, and many others can be thoroughly mixed effectively and quickly.

Spin Casting Machines

With more than 40 years of experience in spin casting systems, StateMix’s spin casting machines provide a unique solution for casting parts that cannot be poured via conventional low-pressure methods. Spin casting is used in manufacturing parts such as seals, large O-rings, and sleeves where complete removal of air bubbles is critical. An innovative centrifuge clamping system will automatically lock the mold as soon as it starts to rotate. A DC motor drive can provide a wide range of rotational speeds from 5 to 5000 RPM.

Our spin casting machines are used to cast polyurethane wheels, gaskets, sleeves, sheets, timing belts, and many other products.

MOCA Melter / Automated Tank Stations

Designed specifically to melt and dispense solid curatives such as MOCA or HQEE, the MOCA Melter will heat your materials and degas, if required, while agitating the material under vacuum, and automatically dispense the amount of material that you enter into the computer. Since the tank assembly is completely sealed, you can store your sensitive materials under vacuum or a blanket of nitrogen, thus preventing any moisture contamination. Tank size can vary from 5 to 110 gallons (20 to 440 liters).

Other urethane manufacturing accessories:

Rotational Rolls Covering Units

At StateMix, we also develop turnkey systems for rotational casting of industrial rollers. These rollers are primarily used in the pulp and paper, steel, and printing industries and in large conveyer systems. The size of rollers processed with our rotational casting machine can be as large as 6 feet in diameter and 40 feet in length. The rotational casting process is a system in which fast-curing polyurethane systems, which are especially formulated for room temperature applications, are applied to the surface of rolls.

Convection Ovens

Rather than purchasing an oven that is not designed and manufactured for your needs, you can now order an oven that is sized and custom-designed to economically satisfy your unique urethane.

StateMix’s electric convection ovens are designed for heating molds, curing and post-curing cast parts, or for heating raw materials in pails or drums.

By introducing hot air circulation throughout all levels of the oven, all components are brought to a temperature up to 250°F (120°C) homogeneously and very quickly. A variety of sizes and custom designs are available based on specific applications.

Hot Tables

Are unique tools in the cast urethane industry used to heat and process molds that require accurate levelling or have a large horizontal surface.