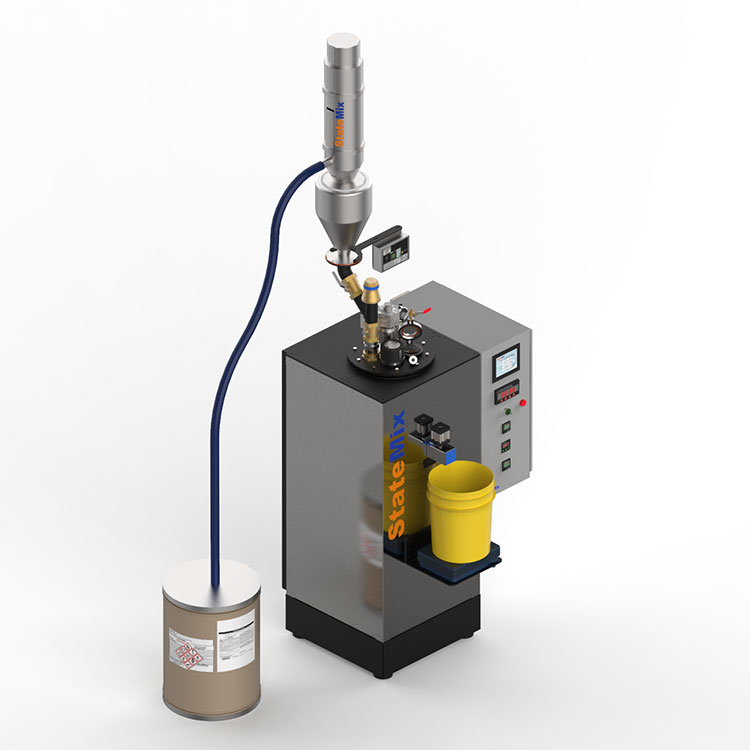

MOCA MELTER AUTOMATED TANK STATIONS

MOCA Melter / Automated Tank Station:

Designed specifically to melt and dispense solid curatives such as MOCA or HQEE. The MOCA Melter will heat your materials and degas*, if required, while agitating the material under vacuum, and automatically dispense the amount of material that you enter into the computer.

Since the tank assembly is completely sealed, you can store your sensitive materials under vacuum* or a blanket of nitrogen, thus preventing any moisture contamination. Tank size can vary from 5 to 110 gallons (20 to 440 liters).

By incorporating the MOCA Melter into your hand batching area, you can:

- Improve your mix accuracy

- Improve the cleanliness of your hand pour area

- Prevent the raw material from contamination

- Provide a safer environment for your staff

Manual Controlled Option:

- Heated line & ball valve

- Vacuum Transfer System with HEPA Filter

- Continuously melt MOCA pellets during the day

- Multiple safety features

- Sealed tank to keep out moisture

Computer Controlled Option:

- All the features of the manual system, plus…

- Touchscreen computer connected to a load cell

- Enter the amount of MOCA required and leave the rest to the computer system

- Save recipes and pour history for quality control purposes

- Computer controlled, heated pneumatic valve

Principal of operation:

The material can be stored in the tank prior to the required processing time. By setting the timer, the contents of the tank can be melted or heated to the desired temperature and ready to be used at the beginning of the shift.

The agitator will ensure that the material inside the tank is heated gradually and homogeneously to prevent any discoloration or heat history to the material. To dispense the material, the operator simply places the container under the computer-controlled valve assembly and enters the required amount.

The computer then opens the valve and begins monitoring the changing value of the scale**. As soon as the desired amount of material is transferred to the container, the valve will close, and a beeper will sound signalling the operator to retrieve the pail from the scale.

*Please note that vacuum pump is not included in standard package.

** Available with computer control option.

Your satisfaction is our highest priority.

If you have any questions or require additional information, please contact us.